Spiral Round Heat Exchanger Pipe Machine: Revolutionizing Heat Exchanger Manufacturing

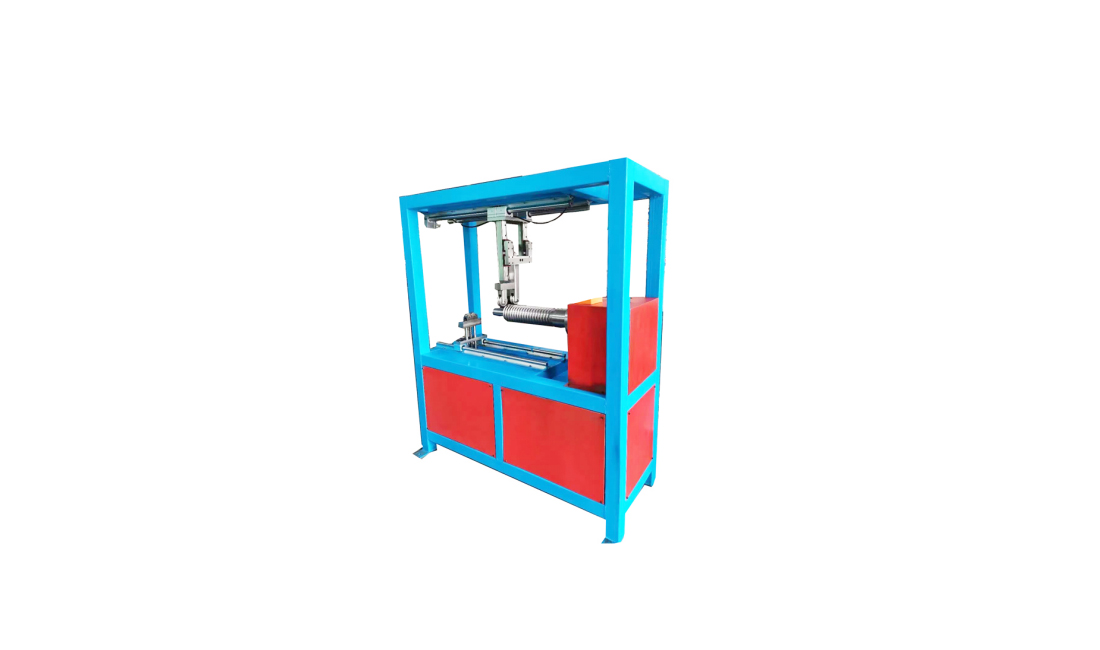

In the ever-evolving landscape of industrial manufacturing, efficiency, precision, and innovation are the cornerstones of success. The Spiral Round Coil Tube Bending Machine, also known as the spiral round heat exchanger pipe machine, stands at the forefront of this technological revolution, transforming how we approach producing critical components for heat exchangers, air conditioners, and radiators.

A New Era in Tube Forming

Imagine a device that can bend metal tubes into perfect spirals with unmatched precision and consistency. That’s exactly what the Spiral Round Coil Tube Bending Machine does. This innovative equipment is reshaping industrial processes, offering manufacturers a way to create complex tubular components with ease and efficiency.

But why is this important? In industries ranging from HVAC to chemical processing, the demand for high-performance heat exchangers is ever-growing. The ability to produce precisely formed spiral coils is crucial for creating efficient, compact, and durable heat exchange systems. This is where our machine steps in, bridging the gap between design requirements and manufacturing capabilities.

The Technology Behind the Machine

Spiral Round Pipe Benders combine mechanical capabilities with advanced electrical control systems. Take the example of bobo machine’s SPIRAL ROUND HEAT EXCHANGER PIPE MACHINE M-16, a machine that gives us an insight into its main features:

1. Precision Bending Capabilities:

●Handles tubes up to 20mm x 1.2mm in diameter (customizable)

●Achieves a minimum bending diameter of just 3 times the tube diameter

●Utilizes cold-forming techniques for superior structural integrity

2. High-Speed Operation:

●Rolling speed of 300mm per minute

●Dramatically reduces production time compared to traditional methods

3. Robust Power and Performance:

●2.5KW motor for consistent power delivery

●Requires 0.45 Mpa air pressure, ensuring stable operation

●Designed for continuous industrial use

4. Versatile Output Specifications:

●Produces coils with a maximum outer diameter of 350mm

●Capable of creating coils up to 650mm in height

●Adaptable to various material types, including stainless steel and copper alloys

5. Cutting-Edge Control Systems:

●Incorporates Delta brand PLC for precise process control

●Features high-response servo motors for accurate movements

●User-friendly interface for easy operation and monitoring

6. Dual-Layer Innovation:

●Unique ability to create double-layer spiral coils

●Expands application range and allows for more complex heat exchanger designs

7. Compact Footprint:

●Machine dimensions of 1500mm x 800mm x 1200mm

●Easily integrated into existing production lines

Applications Across Industries

The versatility of the Spiral Round Coil Tube Bending Machine makes it an invaluable asset across various sectors:

1.HVAC Systems:

○Creates efficient coils for air conditioners and heat pumps

○Enables the production of more compact and energy-efficient units

2.Automotive Manufacturing:

○Produces precise radiator components for enhanced vehicle cooling

○Supports the trend towards more efficient and lighter vehicles

3.Chemical Processing:

○Crafts heat exchanger components for reactors and distillation columns

○Allows for better temperature control in sensitive chemical processes

4.Power Generation:

○Manufactures cooling system components for power plants

○Contributes to improved energy efficiency in power generation

5.Food and Beverage Industry:

○Creates coils for pasteurization and cooling systems

○Ensures food safety through efficient heat transfer

6.Pharmaceutical Manufacturing:

○Produces components for sterilization and temperature control equipment

○Supports the production of temperature-sensitive medications

Operation and Maintenance: Ensuring Longevity

Operating this machine is surprisingly straightforward, thanks to its user-friendly control panel. However, to ensure optimal performance and longevity:

1. Daily Operations:

●Begin with a thorough machine check before starting production

●Ensure proper material feeding to prevent jams or misalignments

●Monitor bending parameters throughout the production run

2. Regular Maintenance:

●Conduct weekly inspections of all moving parts

●Lubricate bearings and sliding components as per manufacturer guidelines

●Check and tighten all bolts and connections monthly

3. Electrical System Care:

●Keep the control panel and electrical components free from dust and moisture

●Regularly update software and backup system settings

●Schedule annual inspections by qualified electricians

4. Troubleshooting:

●Familiarize operators with common issues and their solutions

●Maintain a log of machine performance for early problem detection

Why Choose BOBO Machine?

At BOBO Machine, we pride ourselves on delivering top-quality equipment that meets the evolving needs of the industry. We don’t just sell equipment; we provide comprehensive manufacturing solutions:

1.Quality Assurance:

○Rigorous testing of each machine before shipment

○Use of high-grade materials for all components

2.Customer Support:

○One-year warranty on all parts and labor

○Comprehensive operation training for your staff

○24/7 technical support hotline

3.Customization Options:

○Ability to tailor machine specifications to your unique needs

○Consultation services to optimize your production line

4.Continuous Innovation:

○Ongoing R&D to improve machine capabilities

○Regular software updates to enhance performance

Conclusion

The Spiral Round Coil Tube Bending Machine is more than just a piece of equipment; it’s a gateway to enhanced productivity and quality in heat exchanger manufacturing. By bridging the gap between complex design requirements and manufacturing realities, this machine opens up new possibilities in heat exchanger technology and beyond.

Whether you’re looking to upgrade your manufacturing capabilities or seeking to enter the heat exchanger component market, the Spiral Round Coil Tube Bending Machine offers a competitive edge that’s hard to ignore. With BOBO Machine’s commitment to quality and innovation, you’re not just investing in a machine – you’re partnering with a leader in industrial manufacturing solutions.

Want to Know More About Our Products?

View All Products Now